WIRE CLEANER WITH SATURATED STEAM

This solution has been specifically designed for in-line wire cleaning, where the cross section to be cleaned is small but the line speeds are high. There are various different types of wire, and hence different types of dirt, some of which can be very difficult to remove. The below is a brief summary of the benefits of steam cleaning:

- high levels of degreasing;

- the wire is dry when it is fed out of the system;

- direct in-line cleaning at any speed;

- different diameters and shapes without having to change tools;

- low water consumption (in most cases < 50 lt/hour);

- very little waste water produced (in most cases < 10 lt/hour);

- extremely reduced overall dimensions on the line (in most cases < 2 mt);

- an ecological alternative to the use of solvents.

High degreasing levels: this is an inherent feature of cleaning with steam, which is directly attributable to the high temperature of the steam applied to the wire (greater then 140 °C). Due to the temperature of the steam, the wire is perfectly dry when it is fed out of the system, this eliminates the need for a drying phase, which is indispensable in the other washing systems. Line speed: this is an important factor that leads to the accumulation large quantities of dirt in a short time, especially in the case of wire with larger cross sections. Cleaning with steam represents an ideal solution given the speed at which it heats the surfaces. When using our system it is possible to work at speeds of up to 120 mt/min. Low water consumption: steam cleaning systems use very little water, especially in the case of products with small cross sections, such as wire. Our systems consume between 15 and 100 litres of water per hour. Very little waste water: one of the characteristics that distinguishes steam cleaning systems is that they generate very small quantities of waste water, consisting principally of the dirt that has been removed, together with a small proportion of condensed water vapour. extremely reduced overall dimensions on the line: all our in-line cleaning systems are designed to occupy as little space as possible on the line, thanks to the rapidity of the steam cleaning process. Also, all the auxiliary units are installed remotely. An environmentally friendly alternative to solvent systems: we do not use solvents! Our steam cleaning systems have always represented a truly ecological alternative to the use of solvents. If it is necessary to use detergents, they are recycled continuously, keeping consumption levels to an absolute minimum (typically < 5 litres/day).

WIRE CLEANER WITH DETERGENT RECYCLING

SMALL DIAMETER WIRE CLEANER

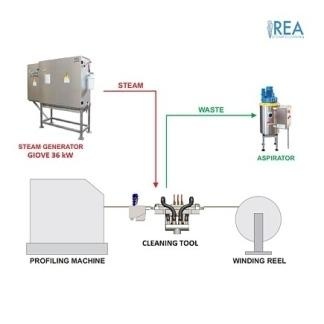

EXAMPLE OF CONTINUOUS WIRE CLEANING INSTALLATION

POST-PROFILING WIRE CLEANER