STEAM CLEANING FOR THE MECHANICAL ENGINEERING INDUSTRY

Thanks to its proven effectiveness in cleaning equipment and instruments, steam is used for a wide range of cleaning and degreasing applications in the mechanical engineering industry. The following is a list of applications where REA Steam Cleaning “Saturno” mobile steam generators and “Giove” fixed systems may both be successfully used. The company, based in Trofarello near Turin, is the leading producer of steam cleaning equipment for the mechanical engineering sector.

- Eliminating oil and dust from printed circuit boards and machine tools

In this case, it is important to perform preventive maintenance in order to ensure continuous operation. The boards are removed from the installation, cleaned and degreased using steam, then dried using a jet of hot, dry compressed air. This eliminates the use of solvents that are harmful both the man and the environment while achieving excellent cleaning and degreasing results.

- Transfers

It is possible to carry out unscheduled cleaning and maintenance, eliminating the dirt that builds up around limit switches, sensors, photo-cells, moving parts such as pistons, slides, spindles, etc., without stopping the machine. Steam can be used to clean electrical components, without damaging them.

- Presses

There are two major cleaning issues that affect in-line sheet metal presses:

1) the first is related to the press itself, and the build-up of dust on elements such as the cooling guards; this limits the passage of air, and can cause the motor to overheat. It is important to emphasize that, when using steam, it is possible to remove the fine powder that is deposited at certain points (for example, clutches, engine sumps etc.) by preventing it from being dispersed in the surrounding atmosphere, thus eliminating the risk to operators.

2) The second issue regards the need to remove the micro-particles that build upon the mold after a certain number of strokes, due to the pitting effect on the sheet metal.

With the “Saturno” system it is possible to clean the die (male and female parts) rapidly without disassembling the mold (thus eliminating the problem of downtime).

- Robot

1) The robots used for transporting motors or components tend to accumulate a lot of dust, therefore it is necessary to clean both the moving mechanical part and the automation section. They can be removed with excellent results.

2) Similarly, it is also possible to clean the robots used for welding, transferring sheet metal from the press to press, painting, etc. Even in these cases, the cleaning is performed quickly and efficiently while fully respecting both the operator’s health and the environment and without causing problems at the electrical level.

- Machine tools

Steam systems also provide significant advantages in machine tool cleaning applications since they can be used to clean areas that are inaccessible to brushes or cloths, rapidly and without damaging electrical parts, while preventing the formation of rust.

- Machined parts

Machined parts may be cleaned manually using our standard accessories, or automatically (when processing large numbers of pieces), using carousel or tunnel systems. In this case, the steam may be super-heated if necessary in order to achieve even more effective results, while maintaining complete respect for the environment.

In large mechanical manufacturing facilities and metal working factories “Saturn” technology is used successfully for degreasing metal surfaces before painting or welding, or cleaning the end products in order to ensure that all traces of the emulsion oils used during the various production phases are eliminated.

These operations may be carried out manually, depending on the type and size of the components to be cleaned or, when cleaning large numbers of items, by means of tunnels, carousels, or dedicated automatic timer-controlled cabins, which do not need to be manned.

INDUSTRY SECTOR

CLEANING COLMUNS

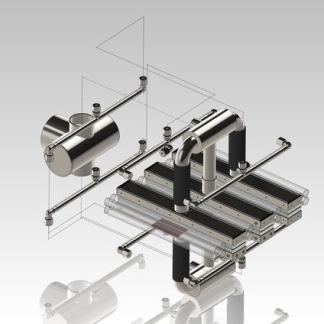

IN-LINE COIL CLEANER

IN-LINE COIL CLEANER

IN-LINE COIL CLEANER

WASHING PROFILES

WASHING PROFILES

BATH CLEANING

PIPE CLEANING TOOL

IN-LINE BAND CLEANING TOOL

CLEANING ENGINES

CLEANING ENGINES

CLEANING

CLEANING

100 KG / H STEAM WAND

CLEANING WITH ROBOT # 1

CLEANING WITH ROBOT # 2

CLEANING WITH ROBOT # 3

CLEANING WITH ROBOT # 4

CLEANING TRAINS

INDUSTRIAL FLOOR CLEANING

INDUSTRIAL FLOOR CLEANING # 2

HEAVY-DUTY CLEANING WITH 100 kg/h STEAM WAND

PRE-COATING CLEANING

CLEANING INJECTION PRESSES

CLEANING INJECTION PRESSES # 2