STEAM CLEANING FOR THE FOOD INDUSTRY

Steam machine is used for a wide range of cleaning and degreasing applications in the food industry (Steam cleaning food industry). Rea Steam Cleaning, steam generators are available in mobile (“Saturno”) and fixed (“Giove”) versions. Both models are suitable for use in a variety of applications, and for cleaning food production and processing machinery, such as:

- Air feeder chains, hooks, moving equipment

It is very difficult to remove build-ups of grease and bacteria from such devices using conventional systems. Thanks to the use of food industry steam cleaning technologies, however, the procedures are faster and simpler, and there is no need to interrupt the production process while cleaning is in progress. The cleaning systems may also be supplied with a small tunnel, upon request, thus completely eliminating the need for an operator.

- Electric saws, circular saws, meat grinder and bag-filling machines, rollers, frames, chains

Normally, the removable parts of these machines can be washed in a bath; Rea Steam Cleaning technology is particularly effective on the supporting structures, where it is easier to carry out the cleaning operations using traditional systems. Thanks to the available accessories it is also possible to reach hard to access parts and recesses, dissolving grease, removing the most persistent encrustations and leaving everything perfectly clean, sanitized and dry.

- Containers, work tables and smooth surfaces in general

When cleaning smooth surfaces it is possible to use a wide range of accessories, including hoods: a single pass dissolves and eliminates the grease, together with the bacterial load. Because it can be completed so quickly, this operation can be repeated several times a day on the surfaces which come into direct contact with food, guaranteeing a high degree of hygiene at all times.

For containers or molds with special shapes, it is possible to request the creation of special tools, both for manual and automatic use.

- Cold rooms

The entire environment (ceiling, walls, floors) can be cleaned and sanitized rapidly, without increasing the relative humidity in the environment, thanks to a special tool that cleans and extracts at the same time. In particular, it is also possible to achieve perfect sanitization of corners, which are natural receptacles of food residues (difficult to remove with conventional systems) and often the source of unpleasant odors.

- Production environments

Special tools, which can be mounted on telescopic rods, have been designed for cleaning and sanitizing the work environment in order to ensure hygienic conditions at all times. These can also be equipped with suction systems, making it easy to clean ceilings, windows, and glazed or tiled walls up to a height of approximately 4 meters. This guarantees operator safety be ensuring that he/she is not obliged to work at heights.

In addition, an optional jointed mop is available for use when cleaning floors, the spaces below machinery, counters, and conveyor belts Not only does this accessory sanitize the surface to be cleaned, it is also able to eliminate waste material from the floor by means of a suction system.

FOOD PRODUCTION SECTOR #1

FOOD PRODUCTION SECTOR #2

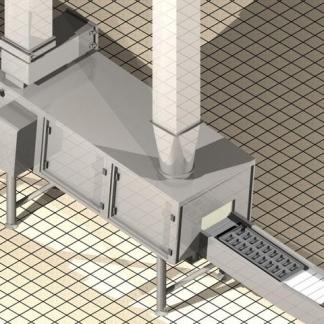

COMPLETE BELT CLEANER INSTALLATION

120 CM BELT CLEANER

FOOD PRODUCTION SECTOR # 3

KNIFE WASHER #1

KNIFE WASHER #2

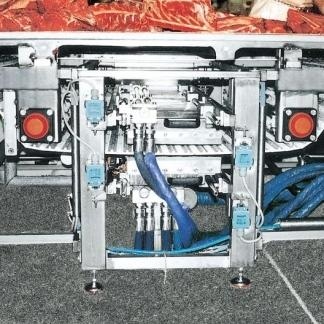

OPEN MEAT BELT CLEANER

PASTEURIZER

REA COOKED FOODS PASTEURIZER - INPUT

SMALL PASTEURIZER

CLEANING FOOD PREPARATION AREA # 1

CLEANING FOOD PREPARATION AREA # 2

CLEANING FOOD PREPARATION AREA # 3

CLEANING FOOD PREPARATION AREA # 4

CLEANING FOOD PREPARATION AREA #5

CLEANING CONVEYOR BELTS

CLEANING CONVEYOR BELT MATS

TUNNEL FOR CLEANING TRAYS

FOOD INDUSTRY

VIDEOS