90% of food contamination occurs during production!

REA INDIA STEAM CLEANING is a specialised manufacturer of in-line cleaning systems, and in particular of “belt cleaner” systems designed to sanitise the conveyor belts used in the food production and processing industry by means of steam cleaning.

Known as “conveyor belt steam cleaners“, these devices fall into three main categories:

- mobile;

- semi-automatic;

- automatic.

All models, irrespective of the category, are equipped with an aspiration system for eliminating the waste material removed by the steam and guarantee the cleanliness of the area where they are used.

They are also very easy to remove from their frames when it is necessary to carry out maintenance work on them (video).

They represent the ideal tool, permitting manufacturers to achieve HACCP standards without the use of detergents.

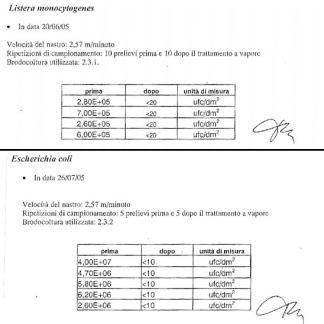

Several tests carried out by specialised laboratories confirm the effectiveness of steam in the disinfection process.

The washing cycle always consists of 2 phases:

- a first phase, during which the belt is washed with steam + water to remove visible dirt and prepare for the second sanitisation phase;

- a second phase, involving the use of steam only at 140 °C, which ensures that all micro-organisms are eliminated.

On the automatic versions (Jolly S2 and Jolly D), the 2 phases are performed sequentially, and automatically without any action on the part of the operator, which means that the cleaning cycle may be run repeatedly during the production process.

STEAM CLEANING AND SANITIZING CONVEYOR BELTS

Mobile steam belt cleaners, 270 VDA and 350 VDA models

NO DETERGENTS –

HACCP protocol

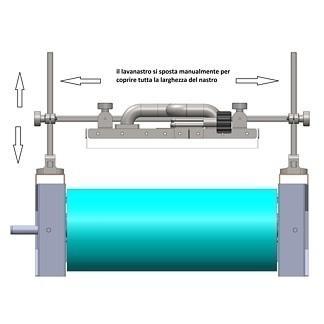

This is the smallest belt cleaner in the range and is designed to be used on belts of varying widths, it can be fastened to the belt rapidly by means of a quick-release system, and may be easily repositioned in order to cover the entire width of the belt (video).

A REA INDIA 9 kw steam generator is perfectly adequate for this economical cleaning solution.

- Built entirely in AISI 304 stainless steel (brushless) it will not damage the belt.

- Washes, sanitises and dries belts of any width, without the need for an operator.

- It can be mounted rapidly on any belt, without the need for tools or modifications to the frame.

- Thanks to its frame, it can be moved to cover the entire width of the belt.

- It can be used on belts of varying widths.

- Complete elimination of steam and residual water, the belt is fed out dry.

- Totally safe for the operator, no steam or water spills.

- Can be used with steam only, or steam + water, depending on the type of contamination.

System components based on device width:

| Width / cm (*) | REA Steam generator | REA extractor |

|---|---|---|

| 25 | Super 9 kw – 15 kg steam / hour – 12 bar | 1200W – 220V (057) |

| 30 | Super 9 kw – 15 kg steam / hour – 12 bar | 1200W – 220V (057) |

| 35 | Special 18kw – steam 30kg / h – 12 bar | 1800W – 380V (059) |

(*) others available on request

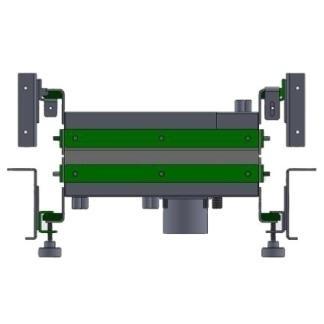

270 VDA BELT CLEANER (LAYOUT)

270 VDA BELT CLEANER (FOR ANY SIZE)

Jolly S1 model – Semi-automatic steam belt cleaner

These belt cleaners are designed to clean and sanitise the belt following production.

This steam cleaning device is mounted in a static position in contact with the conveyor belt, and should be used with plastic, Teflon or smooth steel belts. Depending on requirements, the operator may select steam + water mode in order to remove visible dirt, or steam only mode when sanitising the belt.

Automatic steam belt cleaners – Jolly s2 model for smooth belts, Jolly D model for modular belts

These models do not require the presence of an operator and can be used continuously during the production. They are available for both smooth and modular belts.

Two obvious advantages are:

- elimination of cleaning times and personnel costs;

- the conveyor belt is sanitised at all times during the production process (video), a determining factor in providing customers with a superior quality end product.

Use of the existing steam

Our Giove steam control units are also designed to use pre-existing steam distribution systems. This translates into considerable savings both in terms of investments and operating costs.

STEAMATIC – BELT CLEANERS

STEAM CLEANING AND SANITIZING CHAIN CONVEYOR SYSTEMS

NO DETERGENTS –

HACCP protocol

- Built entirely in AISI 304 stainless steel (brushless) it will not damage the belt.

- Washes, sanitises and dries continuously, during and after production, without the need for an operator.

- Compatible with any width, without modifying the frame.

- Quick assembly, no tools required, can be easily moved from one conveyor to another.

- Complete elimination of steam and contaminated water, the conveyor belt remains dry.

- Totally safe for the operator, no steam or water spills.

- Can be used with steam only, or steam + water, depending on the type of contamination.

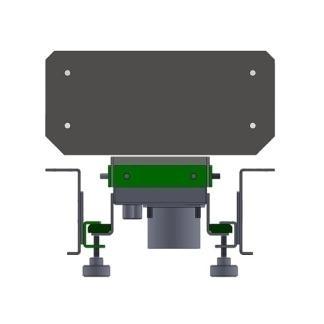

JOLLY S1 MODEL BELT CLEANER

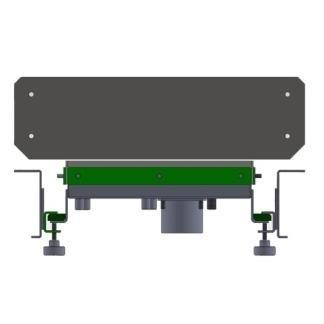

JOLLY S2 MODEL BELT CLEANER

JOLLY D MODEL BELT CLEANER SYSTEM

STEAMATIC MODEL BELT CLEANER

JOLLY S2 MODEL BELT CLEANER

JOLLY S2 MODEL BELT CLEANER

LABORATORY ANALYSES

STEAMATIC MODEL BELT CLEANER

JOLLY D MODEL BELT CLEANER

JOLLY D MODEL BELT CLEANER

STEAMATIC MODEL BELT CLEANER