CLEANING PIPES, PROFILES, AND BARS WITH SATURATED STEAM

All pipes and profiles, irrespective how they are produced, what they are made of, or what they are used for, require in-line cleaning, both during the production phases, and on the finished item, in order to guarantee a top quality end product.

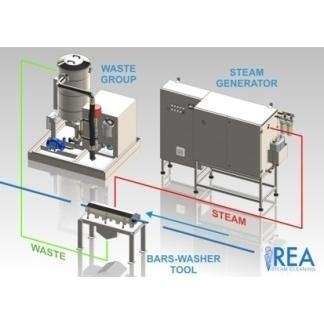

REA STEAM CLEANING manufactures systems for in-line pipe/profile cleaning processes, which are exclusively based on the use of steam since it offers the following advantages:

- high degreasing levels (up to Arcotest 42);

- low water consumption (generally < 50 lt/hour);

- very little wastewater produced (usually < 10 lt/hour);

- extremely small line footprint (usually < 1 mt);

- an environmentally friendly alternative to the use of solvents;

- the interchangeable washing chambers may be used to process different diameters.

High degreasing levels: this is an inherent feature of cleaning with steam, which is directly attributable to the high temperature of the steam.

Low water consumption: steam cleaning uses small quantities of water, especially when working with profiles having small cross sections.

Very little waste water: one of the characteristics that distinguishes steam cleaning systems is that they generate very small quantities of waste water, consisting principally of the dirt that has been removed, together with a small proportion of condensed water vapour.

Extremely small line footprint: all of our on-line cleaning systems are characterised by their extremely compact size, while all the auxiliary units are installed remotely. Thanks to these features, our systems are suitable for installation even in confined spaces on preexisting lines with the minimum of modifications, so that the customer already begins to benefit from cost savings during the installation phase.

An environmentally friendly alternative to solvent systems: we do not use solvents! Our steam cleaning systems have always represented a truly ecological alternative to the use of solvents.

If it is necessary to use detergents, they are recycled continuously, keeping consumption levels to an absolute minimum (typically < 5 litres/day).

Versatility: thanks to our exclusive interchangeable chamber system it is possible to process a wide variety of diameters, with set-up times of less than 5 minutes.

PIPE CLEANER

PIPE CLEANER

PIPE CLEANER WITH INTERCHANGEABLE CHAMBERS